Services

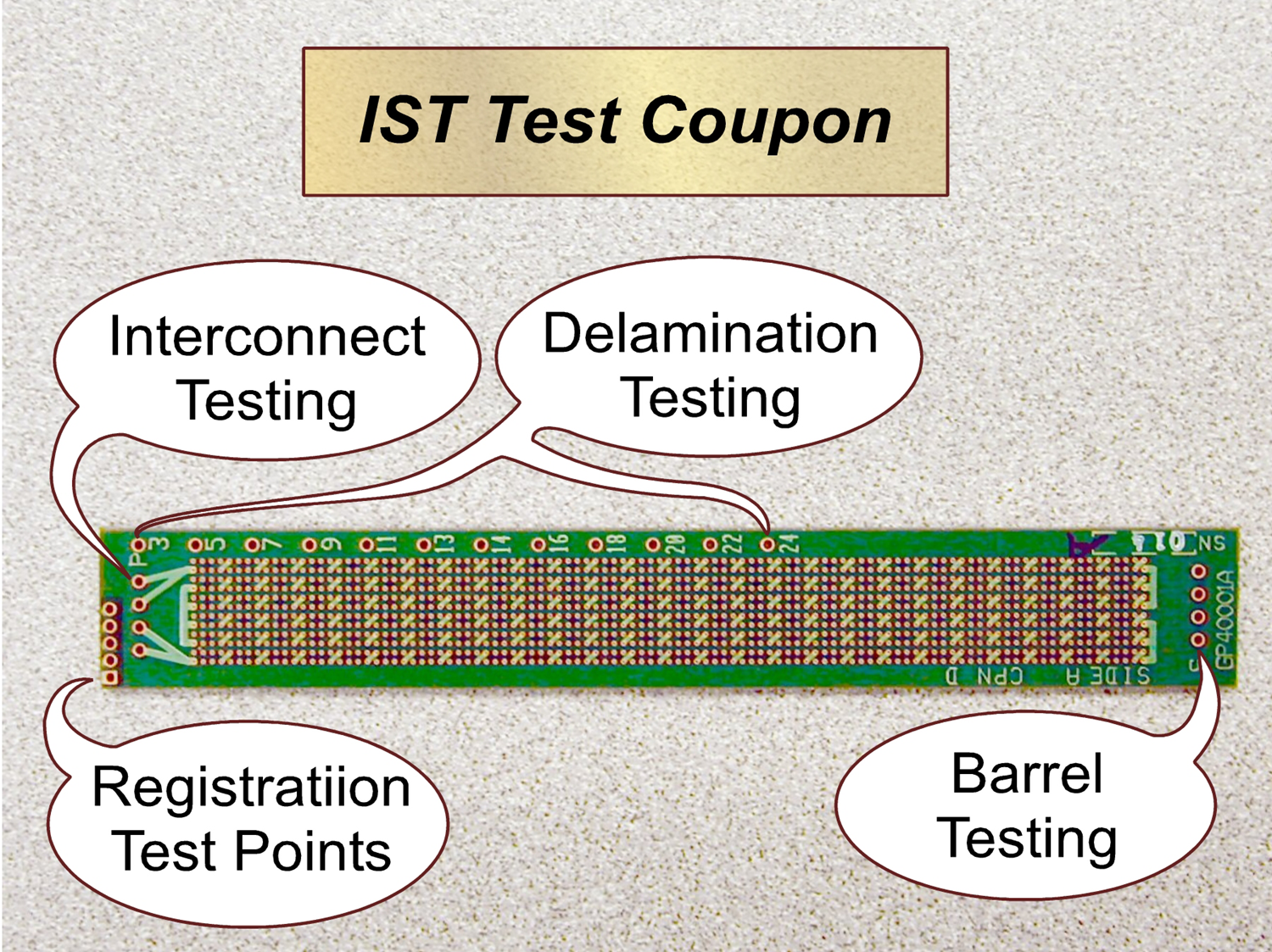

Coupon Inspection and Electrical PrescreenUpon completion of the IST coupon fabrication, a number of individual coupons or test panels are

delivered to the test service facility. PWB Interconnect electrically prescreens and measures all

oupons to verify coupon design and manufacturing consistency. The largest variables are generally

related to Electrolytic copper plating thickness and distribution, additionally, drilled hole to

internal layer misregistration is a common problem. PWB Interconnect documents the findings and

notifies the customer with the prescreening results, including a recommendation related to which

coupons should go forward for IST Testing.

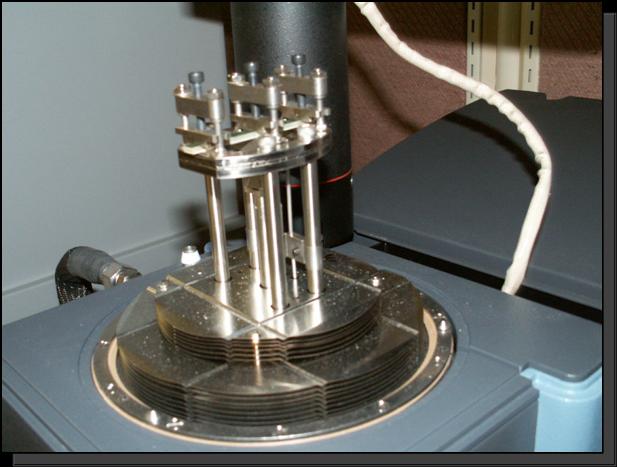

Coupon Testing

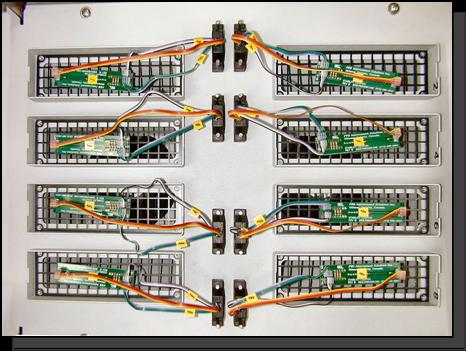

After satisfactorily passing through the electrical prescreen activities and receiving

agreement from the customer to proceed, PWB Interconnect begins the IST testing on the specified

quantity of IST coupons. The coupons are tested until the inception of failure, generally set

at a 10% increase in elevated resistance. The resistance through the PTH Barrel and the resistance

through the inner layer to PTH barrel (or buried via, blind via, micro via) interconnect are

continuously and simultaneously monitored. Once testing is completed, PWB Interconnect provides

a report which identifies the test results with all applicable graphs for each coupon. The results

also include comparison graphs of the products performance to established baselines for products

with similar technology and attributes.

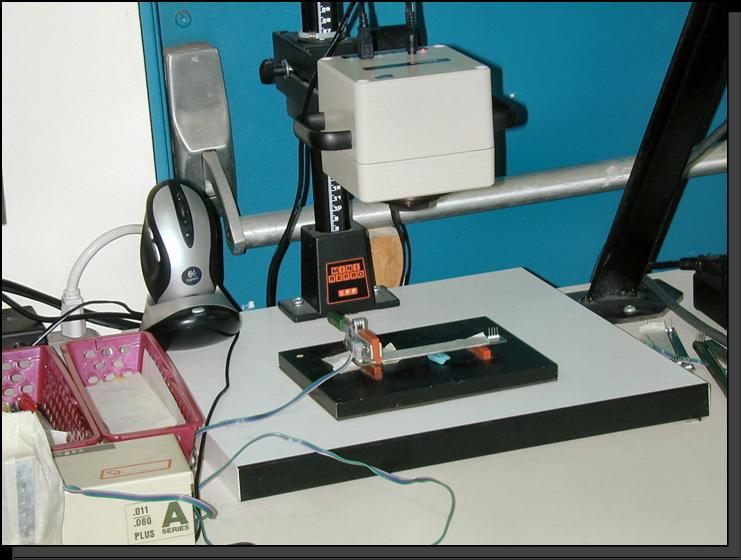

On test completion, PWB Interconnect locates and identifies each failure site in each coupon,

using the Thermographic/Infra Red Photo Imagery process. Depending on how the coupons perform

through IST testing, a low number of microsections are removed and examined to confirm the

interconnect failure mechanism(s).

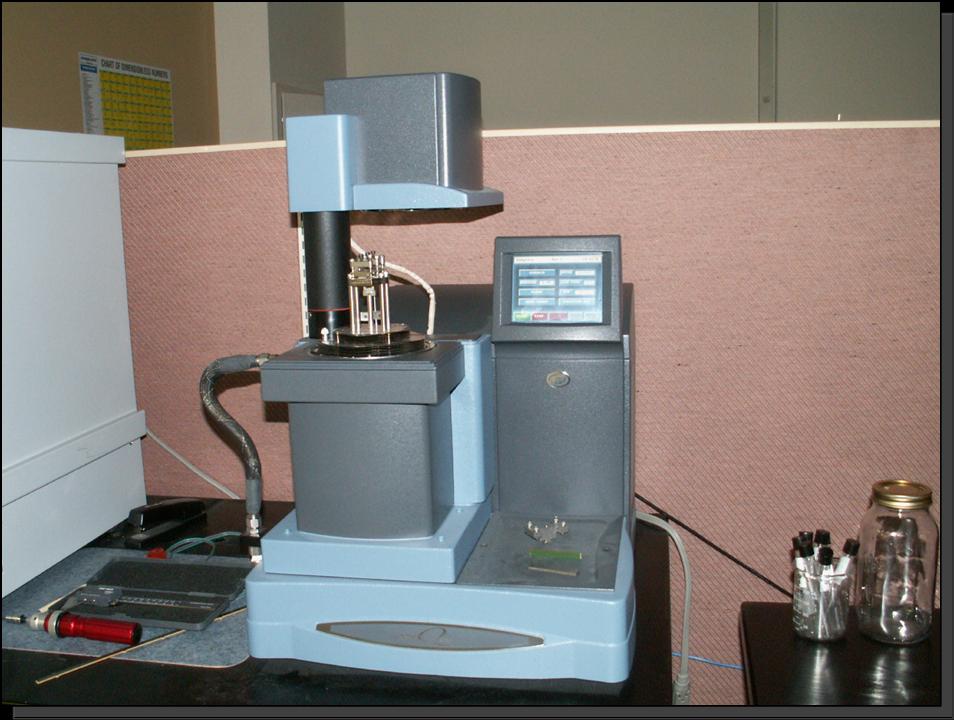

Upon completion of IST testing and failure location, PWB Interconnect performs

adequate failure analysis to confirm the IST findings. The necessary microsectioning analysis

on a TBD (agreed upon with the customer), sampling of the coupons failure sites to visually

assess the failure locations and modes. A final report documenting the findings of the failure

analyses activities shall be prepared with microscopic images. Upon completion of the Failure

Analyses activities, the analyzed specimens and remaining IST coupons shall be labeled, packaged

and returned to the customer.

• Custom coupon design

• Thermal Mechanical Analysis (TMA)

• Dynamic Mechanical Analysis (DMA)

• Product pre-screening

• Product pre-conditioning simulated assembly

• Capacitance Measurement -DELAM protocol

• Single sense

• Single sense high-temperature testing

• Dual sense

• Two or four day turnaround

• Failure location

• Micro-sectioning

• Micro-sectioning – large/custom format

• Micro-section regrinds

• Micro-section solder floats

• Report writing

• Additional statistical analysis- Weibull