Interconnect Stress Test Technology

For the printed wiring board (PWB), Interconnect Stress Test (IST) Technology performs a much-needed

accelerated reliability/performance assessment, assembly, and end-use industries that is presently

unavailable with traditional accelerated stress testing and microsection analysis. The accelerated

stress testing is performed within a similar time frame and cost to traditional Microsectioning.

Meeting IPC compliancy to TM-650 2.6.26 in 2000, IST is the new industry-standard test method for the assessment of

PWB interconnect reliability. It is an accepted accelerated stress test

method (TM-650 - Method 2.6.26)

for the assessment of Plated-Through Holes (PTH) and inner layer to PTH barrel inter-connections.

Interconnect Stress Testing (IST) technology was original developed from the electrical stress

testing concept called "power cycling," developed by Mr. Rama Munikoti (et. al.) at Northern

Telecom (Nortel) in the mid 80’s. Our IST developers (who also worked at Nortel at that time) had the

responsibility of manufacturing the various types of test vehicles, with known good and bad levels of

quality, specifically in the drilling and Plated-Through Holes (PTH) process. The different quality

conditions supported the viability for the original power cycling concept.

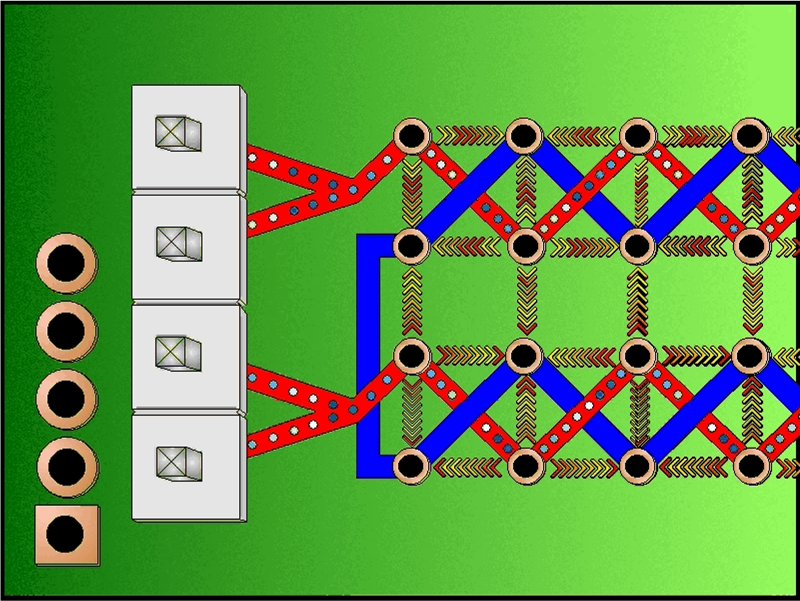

The principles behind Interconnect Stress Testing (IST) are quite interesting and surprisingly simple.

The IST system automatically passes a predetermined constant DC current through a specifically designed

PWB interconnect test vehicle (coupon), the current elevates the temperature of the metals and adjacent

materials. The temperature to which the coupon is heated is directly proportional to the measured resistance

and the amount of current that is passed through the conductors, pads, and holes.

Learn more about IST Technology

IST Features, Applications, and Benefits

|

Features |

Applications |

Benefits |

Protocol |

Automated Interconnect Stress Testing of PWBs |

Evaluation of PWBs' quality, reliability and life. |

Provides objective evidence of the overall quality of PWBs |

Simplified Controls and Easy to Understand Graphs |

Ideal for technician level operation |

Reduces error, down time and misinterpretation |

|

Flexible Testing Parameters |

Specialized, Modified and Directed Studies |

Allows the ability to accelerate the failure relative to the use environment temperatures |

|

|

|

|

|

Analysis |

Tests the Integrity of the PTH and Internal Interconnections |

Testing the strength of the PTH barrel and inter-layer connections |

Objective, quantifiable and repeatable evidence of the quality of PTH and internal interconnections. |

Objective Results |

Product evaluation, troubleshooting, process control |

Removes the dependence on subjective evaluations |

|

Statistically Significant Sample Sizes |

Process and Product analysis, MRB, CAR, First Article Acceptance |

Assures that sample results better represent the population being tested |

|

|

|

|

|

Methodology |

Determine Cycles to Failure Under Different Test Conditions |

Evaluation of PWBs ability to function after simulated Assembly and Rework |

Allows objective ranking of a PWBs longevity in the field by measuring cycles to failure |

Determines the Exact Cause of Failure |

Finding causes of failure for Procurement, Process, Material & Design Evaluations |

Allows the precise and exact determination of the cause for failure |

|

Determination of Hidden or Latent Modes of Failure That Have Not Been Expressed |

Finding causes of failure for Procurement, Process, Materials, & Design Evaluations |

Allows the evaluation and anticipation of undemonstrated defect that are developing |

|

Standardized by IPC 650 TM 2.6.26 |

Establishes an Industry Standard this can be used within the Electronics Industry |

Assurance that methods are consistent with industry reviewed & approved criteria. |

|

Quick, Repeatable and Reproducible Results |

A practical test for quick turn, fast paced OEMs, CMs, Fabricators & Support Industries |

Real Time Data, Problems are found quickly usually within 24 hours of testing |

|

Data for Individual or Grouped Coupons |

Directed Studies or Overview Evaluations of Material, Design or Process |

Allow flexibility in data review and analysis |

|

Precise Identification of Failure Modes |

For finding, evaluating and resolving exact causes of failure |

Unparallel insight to specific causes of failure, and the identification of latent defects |

|

Precise Failure Location |

For finding, evaluating and resolving exact causes of failure |

Examination of the specific PWB feature (PTH, VIA, Interconnect) that is failing. |

|

Simulate the Stress of Assembly and Rework |

Product Life Studies, Reliability Evaluations, Mean Time to Failure Investigations |

Produces data that better represents real environment conditions in a standardized and controlled method |