|

|

|

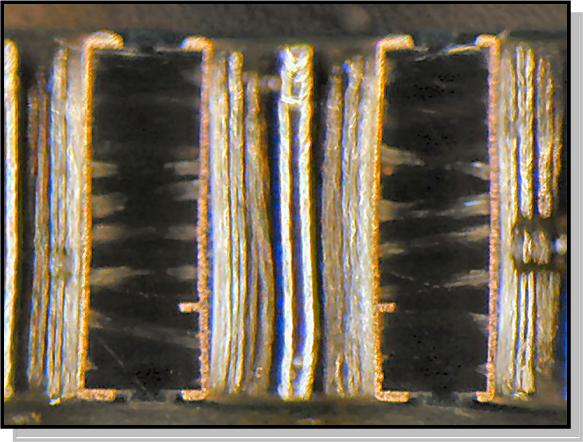

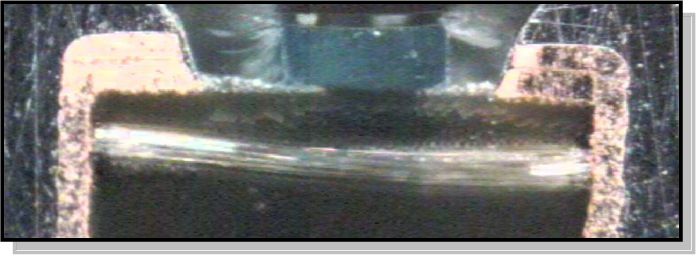

Crazing Failure

This condition may be described as a separation between the epoxy and individual glass fibers.

This is a more insidious failure mode, in that there are no obvious visible cracks,

but it can be seen as light refraction observed along glass fibers that are parallel with the plane of the microsection.

There is a reluctance to label this condition as delamination, but the effects are similar.

Capacitance changes are observed if this condition develops or increases in response to thermal excisions associated with assembly,

rework or reliability testing. Dark field microscopy may be useful to better visualize the magnitude of glass to resin separation.

Crazing is thought to play a role in CAF type failures by providing a path for electro-chemical migration.

The size of these cracks promotes capillary action if liquids are present. If crazing occurs before aqueous

processes during fabrication, then liquids may penetrate along the glass fibers. This situation is further

exacerbated by the presence of an electrical bias, which can cause the migration of ionic contaminants, bridging

between adjacent features. This condition is implicated in field failures that are developed over time,

particularly when there is high electrical bias in a humid environment accompanied by thermal cycling.